Cannabis Clues

RSO Guide: How to Make Cannabis Oil (RSO – Rick Simpson Oil)

Have you ever found yourself with a bumper crop that you simply cannot smoke all of? Or perhaps your plants were robust, but the flowers lacked bag appeal. These are perfect reasons to consider making RSO – Rick Simpson Oil.

RSO can be used to make very potent edibles, drinks, tinctures, and more. By following this guide you will learn how to make an very concentrated cannabis oil.

Learn to Grow Better Weed

Download our free guide to growing amazing cannabis at home.

Click Here For More Info

Who is Rick Simpson?

What is RSO?

Safety First

Remember, alcohol is highly flammable so don’t have any open flames nearby. The alcohol fumes are also flammable so do the distilling process in a well-ventilated area.

Decarboxylation of the flower in a jar has its dangers. Glass can shatter with fast temperature fluctuations. Use weed that is dried and chopped up. Fill the jars only halfway max. Place jars in a cool oven and then turn it on. When completed, turn the oven off and leave jars inside to cool.

Common Problems and Tips

If your oil is not strong, make sure you have decarbed your cannabis. Decarbing turns THCA into THC and greatly increases potency. Inactive oil needs to be heated to transform THCA in THC.

While some people use a slow cooker or rice cooker, the alcohol will be lost to evaporation. Due to the flammable alcohol vapor, it’s strongly advised to try this method outdoors only. Reclaiming the alcohol can save you a lot of money because it can be used over and over again.

Keep the process as cold as possible to limit impurities. Plant material contains more than just THC. Other plant oils and waxes can get into your final alcohol solution. By keeping it cold, they are less likely to.

WeedBOT is your AI assistant for cannabis cultivation. Available 24/7, it provides answers and personalized guidance tailored to your growing needs.

Whether you're a beginner or an experienced grower, WeedBOT helps troubleshoot issues and offers practical tips to improve your gardening experience.

Required Tools For Making RSO

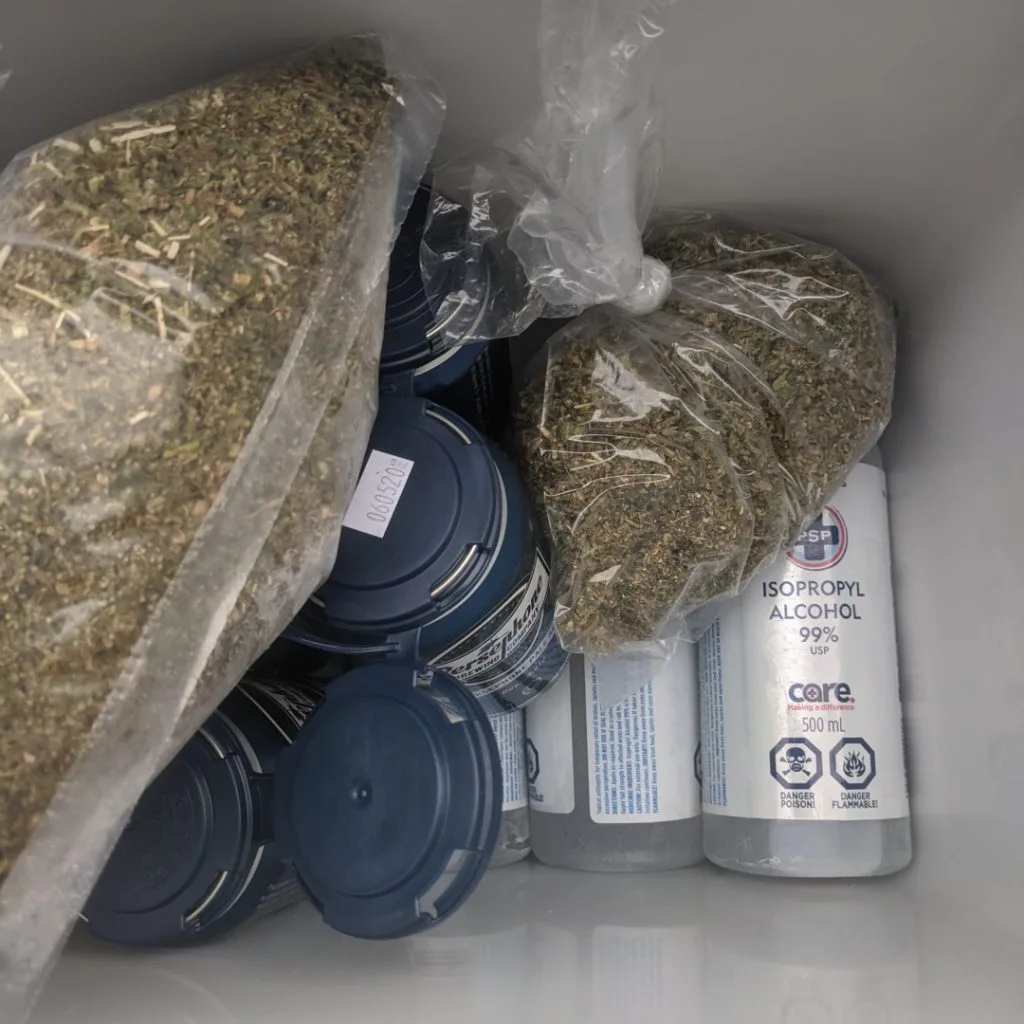

- Dried cured cannabis

- Glass canning jars with lids

- An oven

- A very pure solvent such as 99.99% Isopropyl Alcohol

- Herb Grinder

- Sieve or colander

- Cheese cloth

- Distiller (Amazon Affiliate Link) (or slow cooker with caution)

- Food grade syringes (like these off Amazon)

The Steps To Making RSO

STEP 1: Prepare and Decarb Cannabis

STEP 2: Freeze Weed and Alcohol

STEP 3: First Wash

STEP 4: Second Wash (Optional)

STEP 5: Add Solution to Distiller

STEP 6: Collect Oil in Syringe

Step by Step Guide

The trick to making RSO is to limit the loss of cannabinoids and terpenes, while also reducing the amount of impurities. Cured cannabis has less chlorophyll, which can taste bad and cause tummy irritation.

STEP 1: Prepare and Decarb Cannabis

Start with dried and cured cannabis that has been milled (chopped up). We are going to decarb it in a jar in the oven. Fill jars halfway with milled flower, seal, and place on the side in a cold oven. Set the oven to 120C or 250F and let it decarb for 45 minutes to 1 hour. Turn off the oven and let it cool slowly inside. Decarbed weed can be stored in the freezer.

What is Decarboxylization?

STEP 2: Freeze Weed and Alcohol

Chill the decarbed weed and alcohol in the freezer. You want enough alcohol to fill the jar of decarbed weed. The colder the better, to limit impurities.

Learn to Grow Better Weed

Download our free guide to growing amazing cannabis at home.

Click Here For More Info

STEP 3: First Wash

Pour the ice-cold alcohol into the jar of decarbed weed, give it a shake, and then filter out the plant material with a sieve and cheese cloth.

The “first wash” is a crucial step in the extraction process to create a cannabis tincture. Here’s how it works:

-

Pour the Ice-Cold Alcohol: The first step involves pouring the ice-cold alcohol into the jar containing decarboxylated (activated) cannabis. The alcohol acts as a solvent, pulling out the active compounds from the cannabis plant, including THC and other cannabinoids.

-

Shake the Mixture: After adding the alcohol, the next step is to shake the mixture. This helps to thoroughly mix the cannabis with the alcohol and aids in the extraction process.

-

Filter Out the Plant Material: Once the cannabis and alcohol have been adequately mixed, the next step is to filter out the plant material. This is typically done using a sieve and cheesecloth. The sieve helps to separate the larger pieces of plant material, while the cheesecloth catches any smaller particles.

The liquid that remains after this process is a potent cannabis tincture. It’s important to note that this is just the “first wash.” The used plant material can be washed again to extract more of the active compounds, but the first wash generally yields the most potent results.

What Type of Alcohol or Solvent Can I Use For Making RSO?

What Can I Do With The Leftover Plant Material?

- Reuse for Second Extraction: You can attempt a second extraction to get any remaining cannabinoids that might not have been extracted the first time.

- Make Edibles: Although the potency will be much lower, you can use the leftover material to make cannabis-infused butter or oil, which can then be used in cooking or baking.

- Compost It: If you have a garden, the plant material can be composted and used to enrich the soil.

STEP 4: Second Wash (Optional)

A second wash with the same decarbed can create slightly more oil but there’s a risk of added impurities.

You can store the jar with the decarbed cannabis alcohol solution in the freezer until ready for distilling.

STEP 5: Add Solution to Distiller

Add the alcohol solution to the distiller. The distiller will keep the temperature high enough to evaporate the alcohol but low enough to avoid excessive terpene loss. The distiller will do its thing and collect evaporated alcohol in a jug. Let the distiller cool slightly before opening to avoid getting hit by a cloud of alcohol vapour.

STEP 6: Collect Oil in Syringe

Inside the container, there will be a thick, black, sticky oil. Carefully collect the oil with a syringe and store it in a cool, dark, secure place until ready to use.

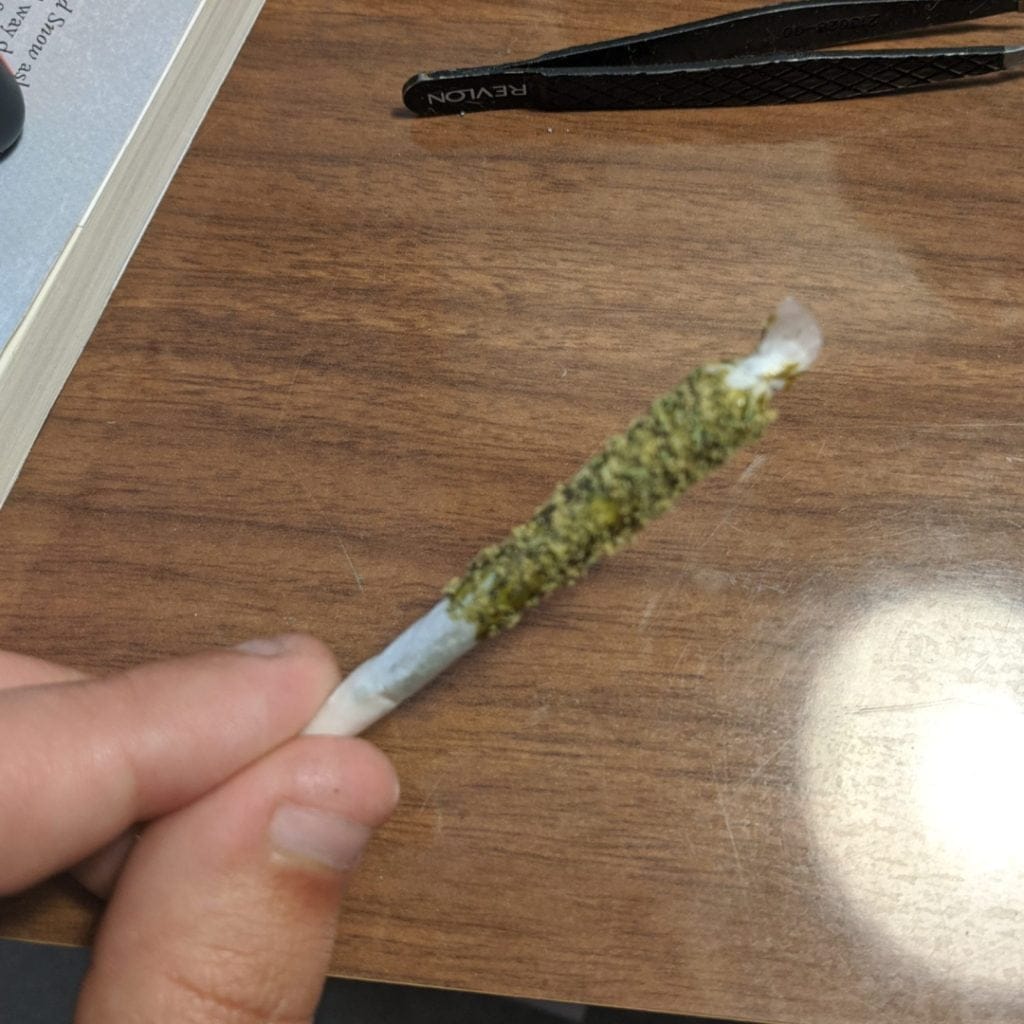

The oil is active and can be used immediately without cooking. It can be added to capsules or used in edibles. It’s very strong when active, so a little goes a long way. When adding to a recipe, make sure it is mixed in evenly or you won’t have consistent edibles. It will mix better if it’s warm. Since the oil can get very thick, you can thin it out with something like olive oil or MCT. RSO can also be placed on joints for a little extra oomph.

How Much Weed Do I Need to Make RSO

To produce high quality RSO for medical use, Rick Simpson recommends using a pound or more of dry bud from very potent and sedative medicinal Indica varieties or Indica dominant Sativa crosses, which preferably contain no more than 10% Sativa. Specifically, to perform a full 60 gram or 60 ml oil extraction, you will need 450 to 500 grams of high quality bud material which is completely dry.

Conclusion

Making RSO at home can be a rewarding process, especially when you have an abundance of cannabis that you can’t smoke all of. With the right tools and safety precautions, you can create your own cannabis oil and enjoy its benefits.

If you want to learn even more about growing good cannabis, we offer a free 40+ page guide full of images.

Now available on Amazon.

Sign up for our newsletter and download the digital copy today!

This guide will answer many questions about growing cannabis, like the following...

✔ Selecting Seeds

✔ Identify and Correct Problems

✔ Maximize Yield

✔ Much More...

Get a Chance to INSTANTLY WIN a Reefertilizer Nutrient Kit When You Sign Up.

Mike Drouin is the co-founder of Reefertilizer. He’s an experienced craft cannabis grower and a writer of many articles regarding the process. Mike lives on Vancouver Island and enjoys cycling and camping and will sometimes combine the two.